Smarter Quality Management for Lithium-Ion Battery Production: Insights from the University of Oulu

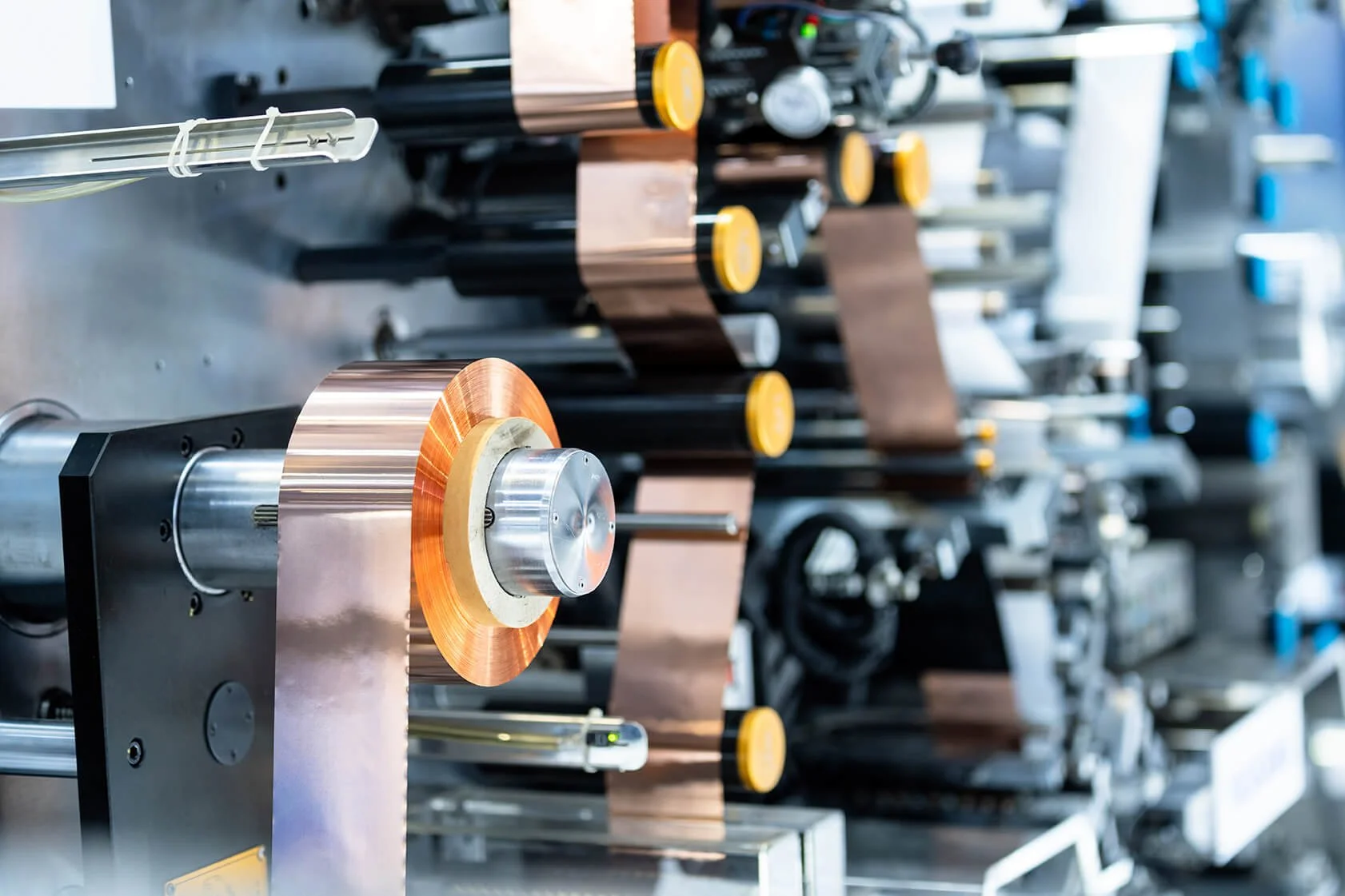

Lithium battery production.

As global demand for lithium-ion batteries accelerates, manufacturers face increasing pressure to improve product quality, consistency, and yield—especially in large-scale roll-to-roll (R2R) production. Variations in slurry formulation, coating thickness, calendering, and separator properties can all impact performance, safety, and lifespan.

Recent research conducted at the University of Oulu, Faculty of Technology, has taken a closer look at how ACA Systems’ measurement instruments can support advanced quality management in battery manufacturing. In his master’s thesis, “Applicability of New Industrial Measuring Instruments in Quality Management of the Battery Manufacturing Process”, Aleksi Paldanius evaluated four ACA Systems instruments across key process stages to determine their suitability for lithium-ion battery production environments.

Evaluating Key Battery Material Properties

The study focused on four fundamental parameters affecting electrode and separator quality:

• Viscosity and water retention of battery slurries

• Roll hardness profiles of coated foils

• Air permeability of separator films

Each measurement offers valuable insight into material behavior and process stability—key enablers of consistent, high-performance battery production.

Characterizing Battery Slurry Behavior

Viscosity Measurement – ACA AX-100 (TAPPI T-582)

The ACA AX-100 system was used to characterize the rheological properties of lithium-ion battery slurries. Following the TAPPI T-582 standard, the instrument successfully distinguished between slurries with different particle size distributions. Accurate viscosity measurement is critical for maintaining coating uniformity and film adhesion. The study showed that the AX-100 can help detect deviations early, supporting real-time process adjustments during slurry preparation.

Water Retention Measurement – ACA Flow WR (TAPPI T-701)

The ACA Flow WR was employed to measure water retention—a key factor influencing drying behavior and binder distribution. Following TAPPI T-701, the results provided quantifiable data on how different slurry formulations retain moisture. This information helps optimize drying parameters, reducing energy consumption and minimizing defects such as binder migration or surface cracking.

Together, the AX-100 and Flow WR instruments form a powerful combination for monitoring slurry quality, ensuring consistent coating performance and repeatable electrode properties.

Detecting Process Deviations in Electrode Manufacturing

Roll Hardness Profiling – ACA RoQ

During electrode calendering, consistent mechanical compression is essential to achieve uniform density and porosity. The ACA RoQ handheld hardness tester was used to measure hardness profiles of coated foils, helping identify potential process deviations.

By detecting changes in hardness distribution, manufacturers can quickly locate uneven compression zones or alignment issues. This enables predictive maintenance and improves reproducibility across production batches—an important advantage for gigafactory-scale operations.

Assessing Separator Film Performance

Air Permeability – ACA Permi Lab (Gurley Seconds Method)

Separator films were analyzed using the ACA Permi Lab, which measures air permeability in Gurley seconds—a widely used standard for evaluating separator porosity. The instrument successfully differentiated between separator materials with varying compositions, allowing assessment of porosity and microstructural differences that can influence cell safety and performance.

Such data is invaluable for incoming quality control of raw materials and for monitoring consistency during production.

From Measurement to Actionable Quality Management

Across all measurements, Paldanius concluded that ACA Systems’ instruments are well-suited for quality management in battery manufacturing. The data they provide can be directly linked to process parameters, enabling immediate corrective actions and supporting continuous improvement.

For example:

• AX-100 viscosity data can guide slurry mixing and formulation.

• Flow WR results can optimize drying conditions.

• RoQ hardness profiles can trigger calender adjustments.

• Permi Lab measurements can ensure consistent separator performance.

By integrating these measurements into production control systems, manufacturers can move toward data-driven, closed-loop process management, reducing waste and improving yield.

Conclusion

The University of Oulu study confirms that ACA Systems’ measurement technologies provide reliable, standards-based data to enhance quality management across the lithium-ion battery manufacturing process. From slurry preparation to separator verification, instruments such as the AX-100, Flow WR, RoQ, and Permi Lab offer precise, repeatable insights that help manufacturers produce safer, more consistent, and higher-performing batteries.

As the industry scales up, smart metrology and real-time measurement will play an essential role in achieving the next level of manufacturing excellence—and ACA Systems is proud to contribute to that progress.

Reference

Paldanius, Aleksi. Applicability of New Industrial Measuring Instruments in Quality Management of the Battery Manufacturing Process. University of Oulu, Faculty of Technology, Department of Process Technology, 2025.

Let’s build smarter battery production together

Get in touch with ACA Systems to discuss how our advanced measuring instruments can support your quality management goals.